Lidar

what is it

A lidar is a sensor system that measures the distance and sometimes also the color value of multiple points using a laser. CAM-I supports this type of sensor with 2 different views: cross-section and rollout.

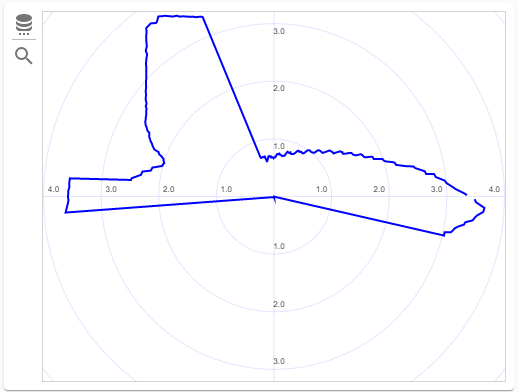

Cross-section

This view shows all the lidar data that was captured at a specific distance in the inspection. This gives a cross-section of the sewer at the current position of the crawler.

info

Lidar cross-section is always available, even when the system is in live-camera mode and not recording, so this view works similar to other sensors like speed, roll, yaw or battery level.

Rollout

This view shows all the lidar data stitched together to form a single image, where each column in the image represents the distance traveled in the sewer and each row represents a single degree of the cross-section. If there is a discrepancy in the wall of the sewer, for instance something protruding from the wall or a cavity is easily detected on this type of image.

info

Rollouts are only available while recording or after recording. This view will not render while in live-camera mode and not recording.

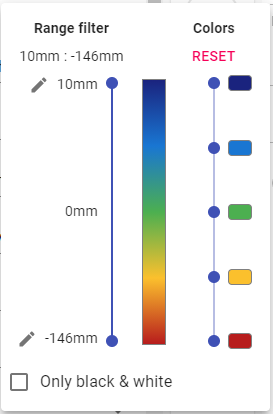

You can configure the rendering engine in the following ways:

- select the value range, used to assign a color to each dot. This can be useful in situations where part of the lidar image contains data at a for greater or lesser distance than the part you are looking at right now. By limiting the range, some features can be made more clearly. To allow maximum flexibility, you can also edit the start and end points. These are pre-calculated by taking the minimum and maximum of the entire image, but as already mentioned, this might sometimes not fit your needs for the current slice you are looking at.

- adjust the colors: by default, blue for things farther away and red for closer by.

- select between black & white or colors

The box at the end shows the currently selected color radient.

info

Colors and range filter are stored together with the lidar data, so your customers can see the image the way you looked at it.

measurements

Thanks to the lidar, it is also possible to perform a number of measurements automatically and very precise.

dimensions

Furthermore, when recording starts, and the system is configured to do so, it will verify the dimensions and when they don't match up (with a difference of about -25 to +25 mm), a dialog box will be shown that allows you to accept, modify or reject the changes.

info

Go to settings and select 'Verify strand dimensions before recording starts' under the 'Strands' section to specify if the system should check for the dimension values before recording starts.

distances and angles

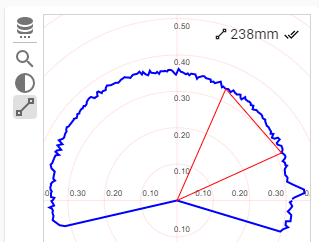

Sometimes, it is also useful to perform a distance or angle measurement of a feature that becomes visible on the lidar. Both the lidar cross-section as well as the rollout views provide different measurment tools that you can use, either to quickly do a temporary measurement or to fill in a value for an observation.

Sometimes, it is also useful to perform a distance or angle measurement of a feature that becomes visible on the lidar. Both the lidar cross-section as well as the rollout views provide different measurment tools that you can use, either to quickly do a temporary measurement or to fill in a value for an observation.All the tools can be activated from the tools menu to the left of the view. Each icon corresponds with the icon that is used in

the observation details to activate a measurement.

Every tool shows the measurement value in the upper right corner. To identify the type of measurement, the corresponding icon is show

in front of each value.

When a tool is active on the lidar view and the measurement button is also pressed in the observation details, than there will be an extra 'accept' button after the value in the upper right corner. By pressing this, you can 'copy' the value into the observation details.

For more details on each type of measurement that can be performed, check out the performing measurements page.